Forgery of documents, counterfeiting banknotes, and alteration of serial numbers and VINs may seem unrelated at first glance. However, what ties all these criminal activities together is the technology used to reveal them.

The technology is based on magneto-optical analysis.

What is magneto-optics in plain English?

The magneto-optic effect refers to the physical phenomenon where the properties of light are altered in the presence of a magnetic field. One of the most well-known examples is the Faraday magneto-optic effect.

According to the Faraday effect, the direction in which the light waves vibrate—known as polarization—begins to rotate in the presence of the magnetic field. The degree of rotation depends on the strength of the magnetic field. The Faraday effect is widely applied in magnetic field imaging and measurement, since it can be used as “magic glasses” to observe the magnetic field.

Nowadays, the magneto-optic effect finds application in various fields, including:

Data storage (CD-MO, DVD-MO);

Magnetic field sensing (especially in the superconductor industry);

Optical communication systems;

Non-destructive testing of metal structures;

Forensic investigations (for obtaining the detailed structure of the magnetic field on the surface of objects being examined)

Since we at Regula specialize in the latter, this article will mostly focus on use cases of forensic examination.

Get posts like this in your inbox with the bi-weekly Regula Blog Digest!

Authenticating banknotes using magneto-optics

In most currencies, banknotes incorporate magnetic protection that, when visualized, repeats some elements from the banknote’s design or its serial number. Magnetic protection is created using magnetic inks, which contain ferromagnetic components that react to the external magnetic field.

Magnetic protection of a Euro banknote

To create magnetic protection for banknotes, different technologies and magnetic inks are used that vary depending on their coercivity, or the ability to resist demagnetization when exposed to external magnetic fields. Coercivity in magnetic print samples can be assessed by analyzing their magnetic hysteresis characteristics, a task efficiently carried out by specialized MO devices like the Regula 7708.

The 50 Euro banknote (First Series) hides magnetic protection in three areas:

The serial number is applied with letterpress printing. Type of magnetic component: SemiHard.

The security thread is embedded in the banknote substrate. Type of magnetic component: LoCo Hard.

The background image fragment is applied with intaglio printing. Type of magnetic component: Soft.

The use of magnetic inks with different coercivity is an additional security layer

Modern ATMs are equipped with scanners that read specific magnetic tags on the surface of the banknote allowing the machine to identify the nominal value of the banknote. However, there have been cases of ATMs failing to detect “supernotes,” highly sophisticated fakes.

Let’s move on to a practical example of advanced lab-based authenticity verification of banknotes using the magento-optical scanner Regula 7701M. This magneto-optical device is intended to carry out magnetic measurements and obtain a magneto-optical topogram, which is a grayscale representation of the magnetic field containing numerical estimates of magnetic induction for each pixel (size 15 µm).

Below is a comparative examination of two banknotes: an authentic one, and a banknote that raised suspicion. The conclusion about the authenticity is based on the assessment of the similarity of the spacial magnetic field distributions for the two topograms.

Special software synthesizes images of banknotes and figures out how magnetic patterns are distributed on them. This data is then used by the software to recognize magnetic security areas on the banknote and analyze how the strengths and patterns differ.

Synthesized images of banknotes’ magnetic protection (A, B) and calculated 2D distributions of magnetic fluxes or magnetic induction (C, D)

As it’s a comparative examination, we’ll overlay the 2D magnetic distributions (C, D) of the two banknotes and see how the magnetic magnitudes compare to each other (E, F in the illustration below).

The analysis of the ratio of magnetic magnitude amplitudes (F) uses color coding:

Gray—no magnetic printing on either sample.

Pink —no magnetic printing on one of the samples.

Red—magnetic values are very different (3 times or more).

Yellow—magnetic values are somewhat different (between 1.5 and 2 times).

Green—magnetic values are quite similar (less than 1.5 times).

Authenticity analysis tells us that the magnetic patterns match almost perfectly, except for some small areas along the edges (about 1 millimeter in size). This suggests that this $100 banknote is genuine.

There are minor (1 mm) mismatches on the edge areas of the magnetic printing (fragments of red edging in the window). This is explained by acceptable errors in printing

Let’s have a look at examination results where objects under study appeared to be counterfeits.

Basic counterfeit

The top image is a “map” of an original banknote; in the middle is the banknote in question; the bottom image shows the results of the amplitude analysis. The distribution of magnetic induction is significantly different.

There’s a lot of red color code, meaning that the amplitude differs by more than three times, and the pink areas indicate that one of the banknotes lacks magnetic ink. These are both significant indicators of forgery.

There are significant mismatches in the magnetic field

Advanced counterfeit

Again, the original banknote is on top, the questioned one is below it, and the results of the amplitude analysis are at the bottom. In both cases, magnetic patterns are present. However, the character of the distribution is different, and, most importantly, the result of the amplitude analysis has a significant proportion of red fill, as well as pink areas.

Although the counterfeiters failed to replicate the amplitudes of the magnetic field, the magnetic patterns look similar. Based on magnetic measurements alone, this sample could be accepted by an ATM

Authenticating printed documents using magneto-optics

Documents printed with a laser or LED printer possess magnetic characteristics because of the presence of magnetic particles in the toner used for printing. When dealing with such types of printed papers, there are three use cases where magneto-optics is a game changer:

Detecting if the entire page was printed on another printer and added to the original set of documents, for example, in a multi-page agreement;

Revealing any symbols, words, or sentences that were added to the original document to alter its content;

Identifying the source to determine whether some documents were printed using the same printer.

Printing verification

Magnetic homogeneity is a crucial parameter for establishing the integrity of printed documents (to see if there are no inserts or additions of text).

The example below illustrates a sample made using three different printers for different lines of a document. The text parameters and printing settings are identical for all printed parts. Visually, the sample document looks homogeneous.

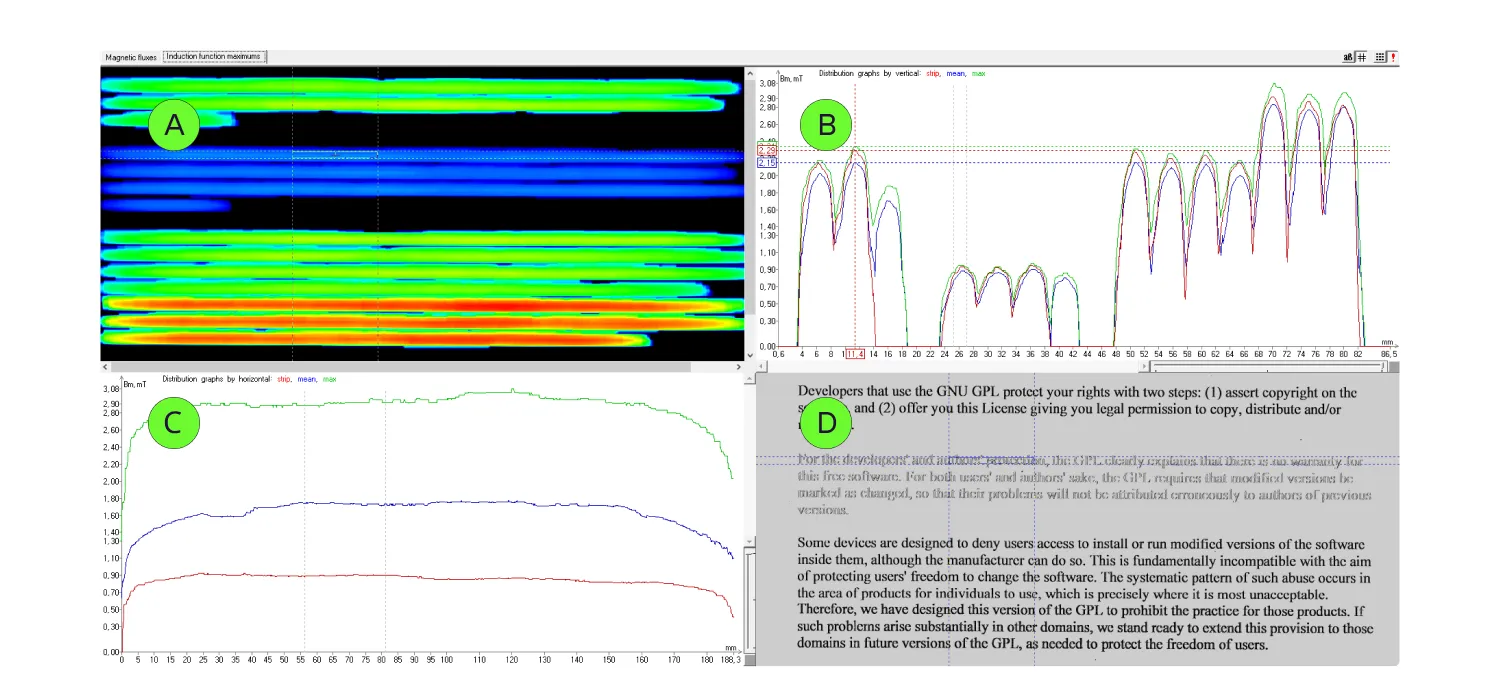

The magneto-optic analysis of magnetic parameters (A), however, shows that three areas of homogeneous printing can be distinguished in the examined document:

Document lines from 1 to 3 and from 8 to 11—marked green;

Document lines from 4 to 7—marked blue;

Document lines from 12 to 14—marked red.

Numerical estimates of magnetic printing differences can also be clearly seen in the graphs of the lines of the document (B).

Calculated 2D distribution of magnetic fluxes or magnetic induction (A), graphs of magnetic field distribution in vertical (B) and horizontal (C) directions, synthesized image of a page (D)

It’s worth noting that detecting printed inserts of small size (word- or character-level analysis) leverages additional algorithms: word detection, creating environment matrices for a set of word locations, calculating local parametric estimates for the environment matrices, etc.

Still, the logic of the process of searching for inserts remains the same: an assessment of magnetic homogeneity is performed to spot any words or characters that differ from the rest in terms of magnetic parameters.

Printing identification

The process of identifying the source of printed documents is based on examining the distinct patterns that printers leave. Every printer applies toner to a page of text with varying thickness, creating unique, printer-specific “fingerprints.” By comparing these print patterns, it’s possible to establish their group identity, indicating the likelihood that they originated from the same printer.

The example below demonstrates the results of comparing two print samples. The samples differ in content but have identical text and print settings. As is evident from the similarity in the shapes of the graphs, their high correlation (C), and the high statistical similarity score (D), the results of the examination are nearly the same for the compared samples.

Synthesized images of pages (A), 3D distributions for the selected parameter (B), graphs of magnetic field distribution in the horizontal direction (C), computational estimation of their similarity (D), location of distributions in the current segment (E)

When comparing samples created by different printers, we can see another picture.

These samples display uniform text characteristics, share identical print parameter settings, and appear visually indistinguishable. However, upon analysis, it becomes apparent that the magnetic induction functions for samples #1 and #2 exhibit significant differences in shape and magnitude, leading to low similarity estimates.

3D distributions (B), as well as graphs of magnetic field distribution in the horizontal direction (C) differ greatly for these two samples, which leads to a low probability of similarity (D, E)

Magneto-optics for checking VIN plates

In compliance with regulations in most countries, all motor vehicles must have a unique 17-character number known as a vehicle identification number, or VIN. This VIN encodes specific information about the particular vehicle: distinctive features, specifications, and manufacturer. It can be used to track recalls, registrations, warranty claims, thefts, and insurance coverage.

When dealing with VIN plates, two common scenarios may arise:

The VIN plate is rusted;

Or, if the car is stolen, the chances are criminals have altered or destroyed the original vehicle number.

Both scenarios are suitable for magneto-optical examination. The technology is capable of restoring the authentic VIN, even if there are no traces of the original numbers left, and examining the surface of nonferromagnetic electrically conductive materials, such as aluminum.

Special magneto-optical devices are used to facilitate this process. One of them is Regula 7505M, a specialized portable workstation, that can be applied both in the field and indoors. We described the details of the VIN restoration process in another article: How to Restore an Obliterated VIN: Chemical Etching vs. Magneto-Optical Imaging.

The original number was removed and over-stamped with new ones. The obtained magneto-optical image reveals the original hidden number

Despite the surface being completely rusty, it was still possible to retrieve the original VIN

Restoration of a removed VIN on an aluminum surface

Defectoscopy using magneto-optics

Magneto-optics plays a vital role in a variety of applications, with a primary focus on gathering crucial surface data. These applications include:

Product quality control in manufacturing processes;

Scientific research of material properties in stressed and deformed states;

Operational diagnostics and defectoscopy;

Investigation of accidents and destruction through instrumental data analysis.

In all these examinations, the surface condition of the object, including the presence and type of defects (such as internal stress areas, cracks, subsurface voids, and foreign material inclusions), holds primary significance. Non-destructive testing (NDT) is also of paramount importance for these research objectives.

Magneto-optical tools exhibit exceptional sensitivity in detecting surface cracks, surpassing the sensitivity of other non-destructive methods. The image below depicts microcracks on the surface of a steel plate and how magneto-optics perform in comparison to capillary and magnetic particle methods.

While surface cracks are barely visible to the naked eye, the magneto-optical examination demonstrated the most distinct results in identifying their true structure

Magneto-optical devices are also useful for examining weld defects. The illustration below shows a welded assembly made by electric arc welding. The photograph of the front surface doesn’t reveal any defects in the welded joint; however, the results of the magneto-optical analysis show uneven weld thickness and a chain of slag inclusions.

Photo of the welded joint (left), magneto-optical image of the welded joint (right)

Examination of archaeological artifacts and art objects using magneto-optics

Another use case where magneto-optical devices excel is working with delicate objects, such as collectible rarities, archaeological artifacts, and works of art. For these items, destructive methods are strictly prohibited, and even minor actions, like surface cleaning, can be considered sacrilegious by collectors.

Nevertheless, these objects often conceal valuable information that remains hidden from plain observation and can only be extracted through instrumental examination.

For example, the Regula 7517 has yielded intriguing results in the examination of collectible weapons, as demonstrated in the January 2022 issue of the German “Vizier” journal. This publication offered a compelling example of how magneto-optics revealed a collectible Colt M1911, previously thought to be a century-old relic, to be modern imitation based on an inexpensive Chinese pistol.

The illustration below shows another examination of a museum specimen of a World War I rifle. Severe surface corrosion has rendered the markings of this object unreadable. However, thanks to the magneto-optical tool, it is possible to confidently visualize the characters of the markings.

The serial number of this relic was totally rusted. The revealed number is 1613

Advantages of magneto-optical examinations

Magneto-optical examinations offer zero cons and numerous pros for various applications. Among the key benefits are:

Non-destructive nature: You can perform assessments using magneto-optical devices multiple times, adjusting the signal’s penetration depth for improved results. The examined surface remains intact.

Sensitivity: The high sensitivity of the MO sensor, in combination with differential data processing algorithms, enables magnetic measurements for microscopic elements of magnetic printing and visualization of low-gradient magnetic fields caused by internal stresses of metal surfaces.

Safety: Unlike chemical examinations, which can damage surfaces and pose health risks, magneto-optical examinations are safe for both the examiner and the material being examined.

Effectiveness on rusty surfaces: Magneto-optical technology is effective even on rusty substrates, and can extract valuable information about the original serial number and subsequent changes.

Adaptability to various surfaces: Magneto-optical technology is well-suited for curved and angled surfaces, making it ideal for VIN and serial number examination. This is in contrast to methods like visualizing with magnetic powder.

Broad material compatibility: It can be applied to both ferromagnetic materials (cast iron, steel) and non-ferromagnetic electrically conductive materials (aluminum alloys, stainless steel), making it a versatile tool for various applications.